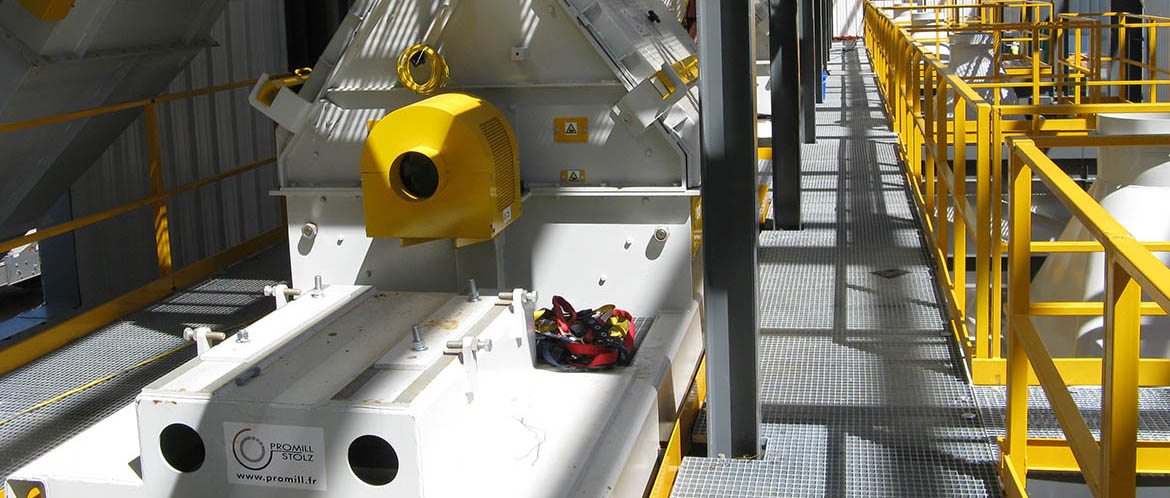

Casey installed the dry hammer milling and pelletizing structure and equipment for a 500,000 ton per year pellet mill facility. The dry hammer mill area consisted of structures, five hammer mills, bins, destoners, conveyor systems, mixers, screens, cyclo-filters, fans, chimney and duct. The pelletizing area consisted of 15 pelletizers, conditioners, bins, conveyor systems, coolers, screens, two bucket elevators, structures, cyclones, fans, chimneys and ducts. Casey also installed and aligned the associated motors and drives.